High Performance Coatings For Oil & Gas Applications

Our SP4 TM Coating is both Smooth and TOUGH, providing Excellent Lubricity along with Corrosion and Wear resistance in the face of Heavy Use and High Temperatures, making it an outstanding coating for oil and gas equipment components. Our proprietary technology combines High Wear resistance, Lubricity and Film Toughness to provide for longer component life. Heat and Pressure Resistance, Scale Resistance and Erosion Resistance combine to allow Extended Performance in the harshest environments. Click to Learn More about SP4

Corrosion is an outstanding challenge faced by the oil and gas sector, costing billions of dollars. Typical mitigation techniques involve surface coatings such as: thermal spray, electrodeposition, and diffusion coatings. Currently, thin film coatings are proving to be highly efficient in

preventing corrosion, wear etc. Thin film coating developed by MVS provides a low- friction, wear and corrosion resistant layer.

SUCCESS FACTORS:

- SP4 coating is highly wear resistant and has proven to withstand over 2000 hrs in a corrosive environment.

- The coating has high surface energy facilitating a slippery surface such that foreign materials cannot adhere to the surface.

MVS SP4 coating creates a surface that:

(a) lowers friction

(b) provides significant corrosion resistance

(c) increases reliability

(d) reduces fouling

(e) lowers maintenance cost

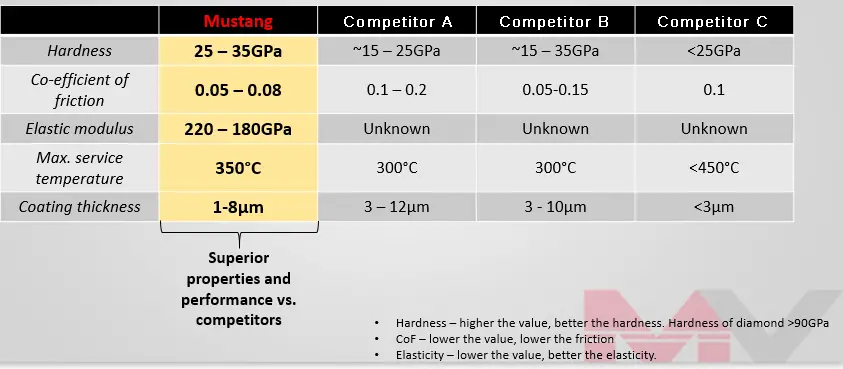

KEY PERFORMANCE INDICATORS:

SP4 has shown to increase the longevity of a surface exposed to corrosive environment with negligible loss of coated material

Coating Services (exclusive):

- SP4™ Carbon Based thin-film wear coatings technology. Our proprietary technology combines High wear resistance, lubricity and film toughness to provide for longer component life. Heat/Cold/Pressure resistant, scale resistant and erosion resistance combine to allow extended performance in the harshest environments. Inherently resistant to chemical attack, this process is appropriate for: gears, bearings, adapters, couplings and leading edge surfaces subject to premature failure. Lubricated and unlubricated applications.

Equipment Solutions: